the difference between laser soldering and soldering iron soldering

as the rapid development of laser soldering technology in recent years, compared with the traditional soldering iron process, laser soldering technology is more advanced, the heating principle is also different from the former, not simply the replacement of the heating part of the soldering iron. laser belongs to the "surface exothermic", heating speed is very fast, while the soldering iron is relying on "heat transfer" slowly heating up.

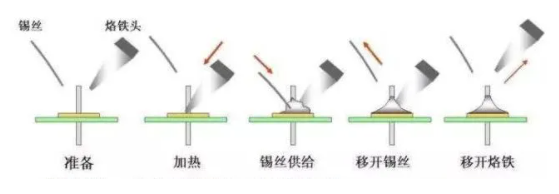

laser soldering process.

laser soldering: to be soldered parts, laser irradiation to warm up → supply tin solder → supply is complete, continue to irradiate the formation of welding → continue irradiation, solder joint shaping → shaping is complete, close the lasersoldering iron soldering: preheat the iron → align the soldering part, heating to a fusible temperature → supply tin solder, continue heating → finish feeding, continue heating → remove the iron, complete the solder joint

the difference between soldering iron and laser soldering

adaptation differences to the surface of the workpiece

when welding some surface complex workpiece, soldering iron soldering due to the iron head and wire feeding device occupies a large space, it is easy to interfere with the surface of the workpiece components. the laser soldering wire feeder with laser heating takes up less space and is more adaptable.

differences in the nature of the components to be soldered

soldering iron soldering is the whole board heating, will cause the whole board together with the heating situation, not applicable to some heat-sensitive components, laser soldering is local heating, the temperature rise of the area around the solder joint is limited, the impact on other original components is smaller.

the contact method of soldering is different

soldering iron soldering using contact welding, soldering iron head will inevitably give a certain pressure on the welding workpiece. however, in some high-end transmission areas, there is a risk of transmission. laser soldering uses non-contact soldering, which does not put pressure on the soldered components and can well prevent the impact on the period due to pressure. also for this reason laser soldering machines cannot directly pressure weld.

differences in consumables

soldering iron soldering process using the iron tip to provide the required heat, with the welding process, the iron tip aging soldering temperature can not meet the welding requirements, it is necessary to replace the iron tip, will increase the cost of welding, while the machine laser welding does not use the iron tip welding will not produce iron tip damage, reducing production costs. and laser soldering when the welding temperature is stable, stable welding quality.

the difference in processing accuracy

soldering iron soldering due to the limitations of the welding process itself, welding accuracy is limited, while laser soldering, the spot can reach the micron level, welding accuracy is much higher than the soldering iron soldering machine welding accuracy.

energy consumption

soldering iron soldering process due to the heating method is the whole board heating caused a lot of heat meaningless loss, increasing the loss of electricity, while the laser welding local heating generated heat consumption is smaller, and not welding when there will be no heat generated to save electricity and reduce costs.

Comments